Description

Description:

Machifit CNC MACH3 Automatic Tool Setting Gauge Z axis Tool Touch Sensor for Engraving Machine CNC Parts

Specification:

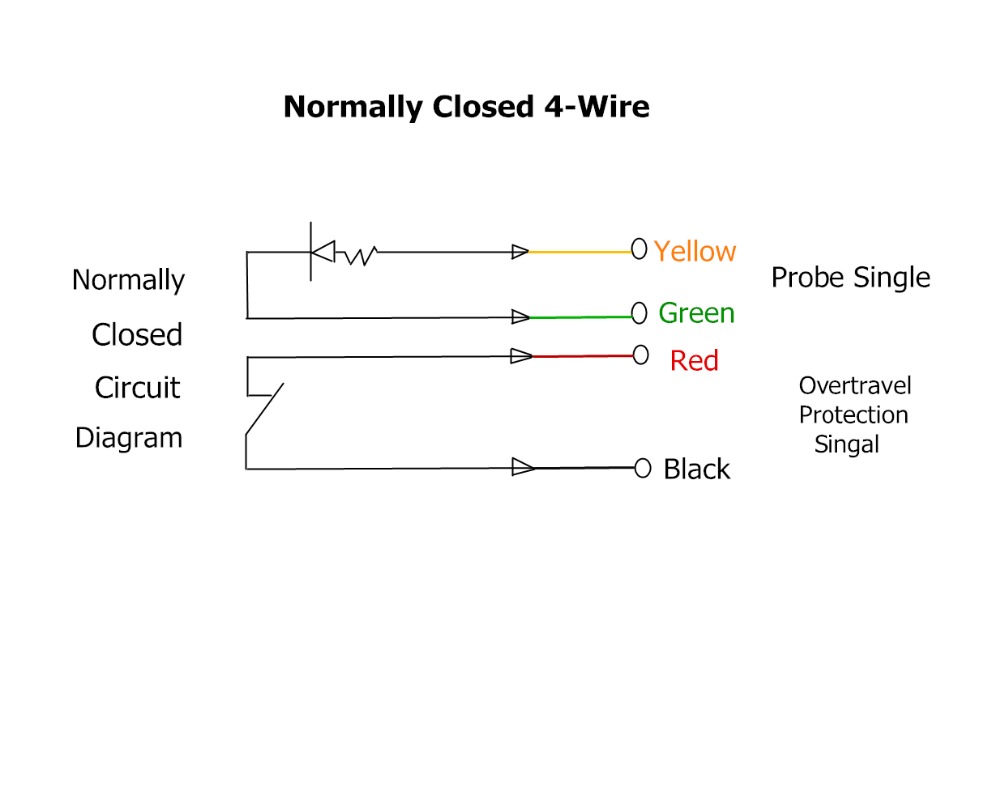

| Output mode |

NC( normally closed ) |

| Pre trip |

Almost 0 |

| Stroke |

5mm |

| Repeat positioning accuracy |

0.001mm(operation speed:50-200mm/min) |

| Life |

3000000 times |

| Contact force |

1.5N |

| Outer shell |

Grinding 4S |

| Protection |

IP67 |

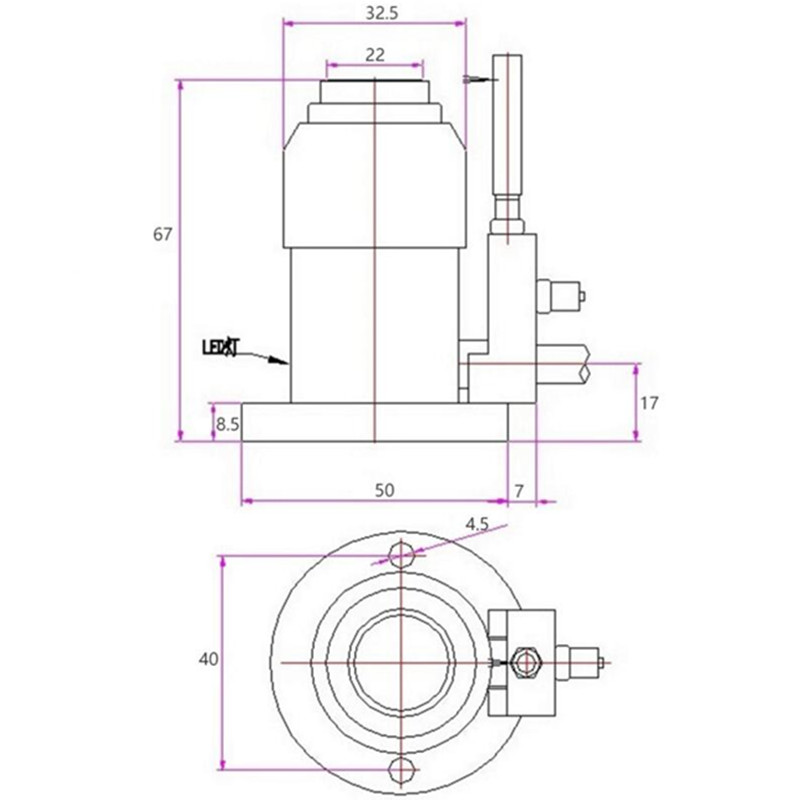

| Cutter head |

Diameter 20mm, hard carbide. |

| Shock rating |

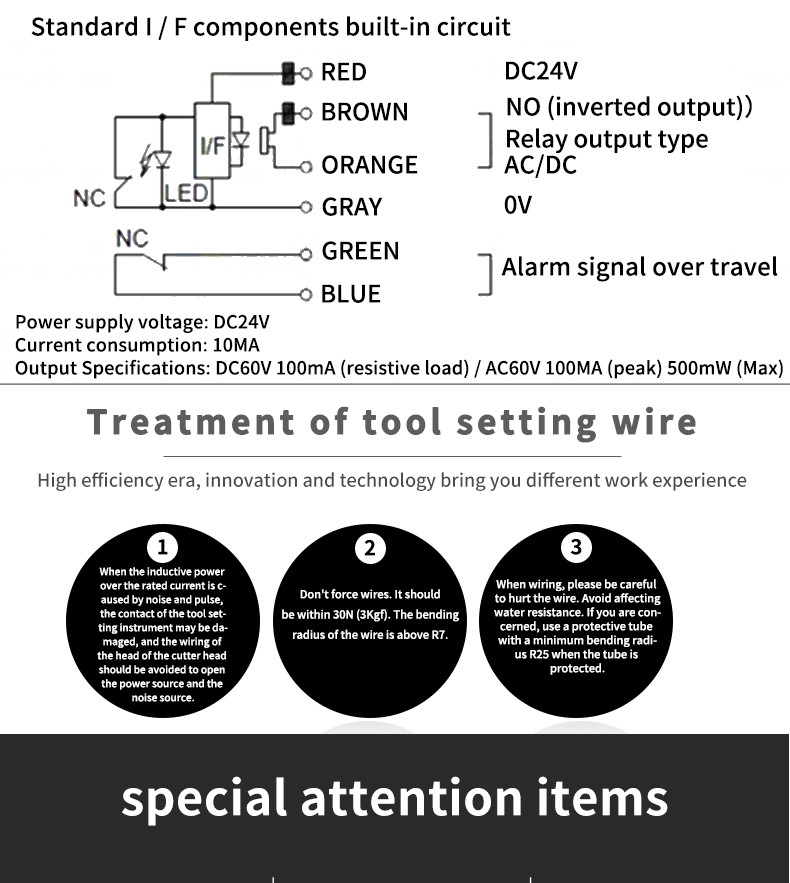

20mA(MAX) DC24V recommended value(10mA)resistive load |

| Cable |

3M 4-cell tensile strength 30N Minimum bending radius R7 |

| Protection Tube |

1M (Minimum bending radius R25) |

| Ultra travel alarm |

|

| Exceed the specifications |

NC(Normally closed),distance signal about 5mm |

| Shock rating |

DC24V 20mA(MAX) 10mA(Resistive load) |

Features:

Waterproof dustproof structure, with good durability for CNC machining jobs.

It can greatly improve the efficiency of tool setting in CNC machining.

It will alert when the stroke is exceeded.

Automatic detection of tool breakage: If the tool is damaged or broken, the machine automatically stops running and warns.

Automatic tool wear compensation: Once the head wear is detected, the relevant program can be corrected to ensure the accuracy of the workpiece.

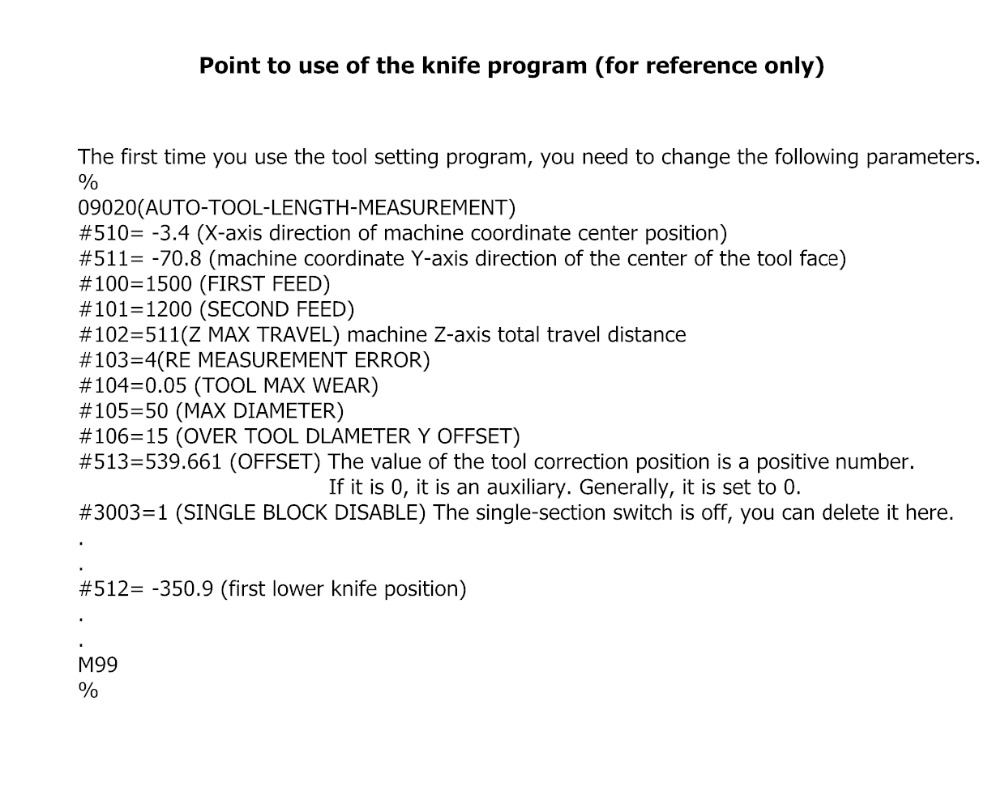

Installation instructions:

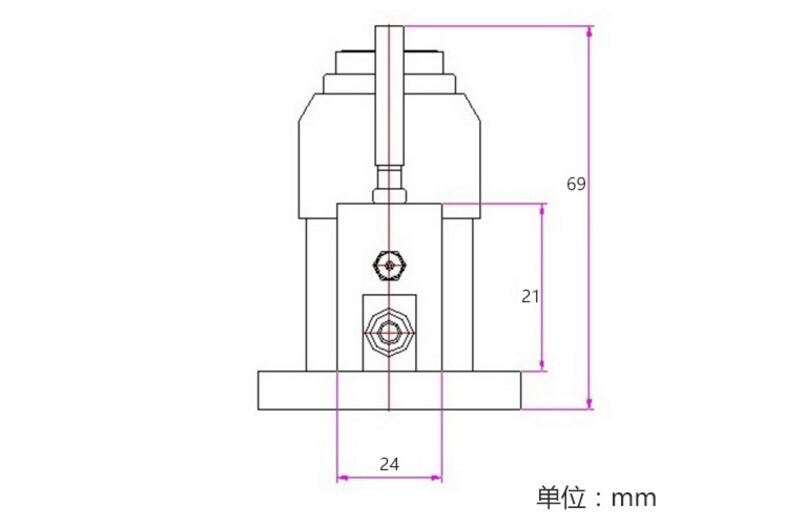

1. The props and the tool setting device must be perpendicular to the contact surface, and vertically contact the contact surface, please install as much as possible on the workbench where the iron filing area is small.

2. Be sure to use the voltage within the rated power supply range, please control the DC10-30V, the current is below 20mA, the ambient temperature range is -25° C-70° C. 3. Please control the cutter tool diameter below 20mm and the cutter speed to be below 50-200mm/min. The tool center should fall to the center of the tool face.

Package Included:

1 x Tool Setting Gauge

More Details:

or 4 payments of

or 4 payments of

Reviews

There are no reviews yet.